In a new video for Cosmo Tech, Renault’s Expert Leader Industrial System 4.0 Jean Goutierre explains how Cosmo Tech’s Prescriptive Simulation Twin brought a new approach to asset obsolescence management and maintenance and reduced capital costs over 5 years from €10 million per year down to 2 and 5 million euros per year.

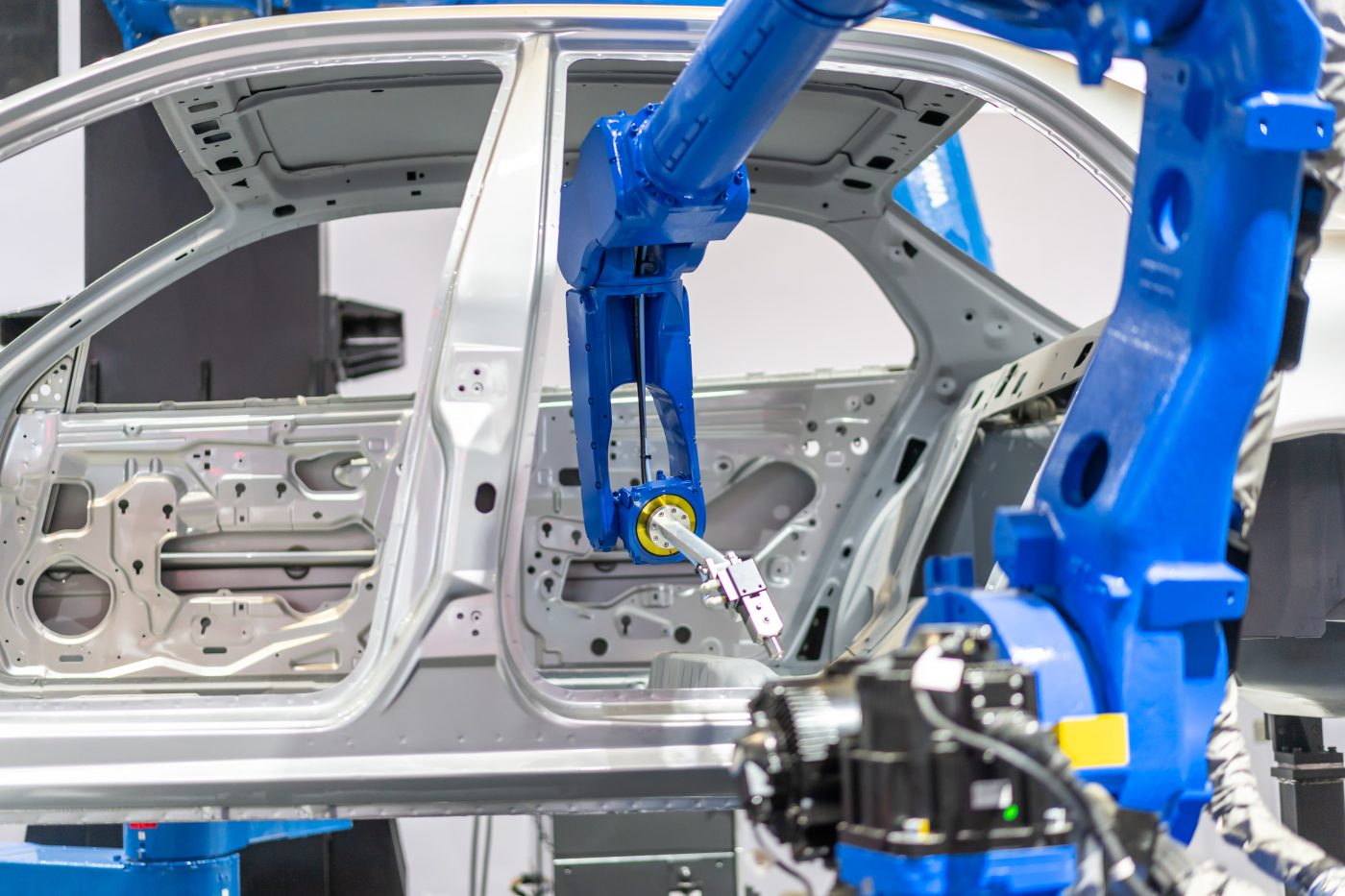

- Manufacturing

- Case Study

Optimize industrial asset investments and control risk

Value creation

- 50%

annual capital investment reduction

⇩

Rationalize maintenance expenditures

⇩

Minimize downtime